Are you ready to turbocharge your automotive manufacturing game? Strap in as we journey through the fascinating world of Liquid Silicone Rubber (LSR) injection molding. This transformative technology could be the turbo boost the automotive industry needs to race ahead!

Section 1: What is LSR Injection Molding?

1.1 Understanding LSR Injection Molding

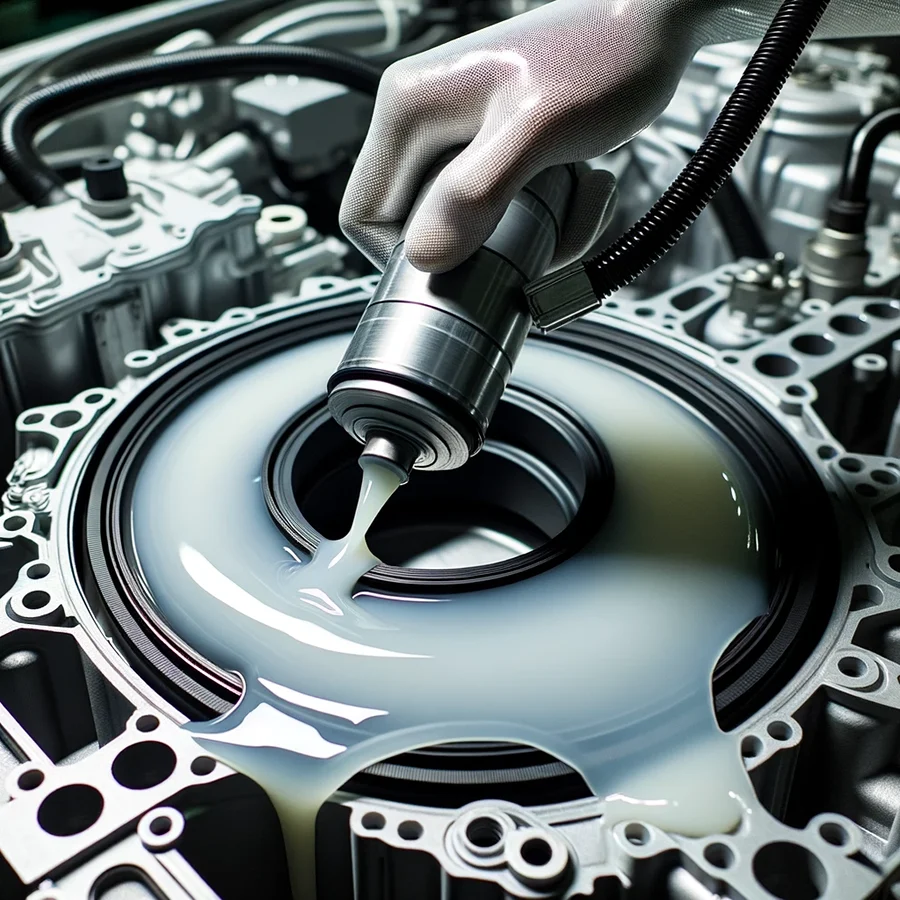

LSR injection molding is a versatile process that uses liquid silicone rubber to create durable, high-quality parts and components. Imagine it as the pit crew of the automotive industry, enabling you to produce efficient, reliable parts consistently.

Section 2: Benefits of LSR Injection Molding

2.1 Enhancing Durability and Performance

Just like a high-performance engine fuels a race car, LSR injection molding fuels the automotive industry with its durability and longevity. The parts produced are resistant to extreme temperatures and environmental conditions.

2.2 High Production Efficiency

Like a well-oiled machine, LSR injection molding ensures smooth and efficient production, reducing waste and saving time. It’s like having a speedster in your production line!

Section 3: LSR Injection Molding in the Automotive Industry

3.1 Creating High-Quality Automotive Parts

LSR injection molding can be used to produce a wide range of automotive parts, from seals and gaskets to LED headlights. It’s like the Swiss army knife of automotive production!

3.2 Meeting Industry Standards

With stringent quality and safety regulations in the automotive industry, LSR injection molding stands as a reliable ally. It ensures compliance with industry standards, providing a safety belt for your production process.

Section 4: The Future of LSR Injection Molding

4.1 Advancements in LSR Technology

With ongoing advancements in LSR technology, the future looks brighter than a set of new LED headlights. The potential for innovation and growth is immense.

4.2 Sustainability and LSR Injection Molding

As the automotive industry shifts towards greener practices, LSR injection molding stands as a sustainable solution. It’s like the electric vehicle of the manufacturing world!

Conclusion

Embracing LSR injection molding is like installing a turbo booster in your manufacturing process. Its benefits range from durability and efficiency to compliance and sustainability. It’s time to shift into high gear and embrace this transformative technology.

FAQs

1. What is LSR Injection Molding?

LSR injection molding is a process that uses liquid silicone rubber to produce durable and high-quality parts.

2. Why should the automotive industry use LSR Injection Molding?

LSR injection molding can enhance durability, efficiency, and compliance with industry standards, making it ideal for the automotive industry.

3. What automotive parts can be made using LSR Injection Molding?

A wide range of parts including seals, gaskets, and LED headlights can be produced using LSR Injection Molding.

4. Is LSR Injection Molding a sustainable solution?

Yes, LSR Injection Molding is a sustainable solution as it reduces waste and promotes efficient production.

5. How does LSR Injection Molding impact the future of the automotive industry?

With advancements in LSR technology, there’s potential for more innovative, high-quality, and sustainable automotive parts production.