As an automotive modification and repair expert, I’m always looking for new and innovative ways to improve the performance and reliability of my vehicles. One of the most exciting new technologies I’ve seen in recent years is liquid silicone rubber (LSR). LSR is a high-performance material with a wide range of applications, including automotive electrical components.

In this blog post, I’ll discuss the role of LSR in automotive electrical components. I’ll also cover some of the benefits of using LSR in these applications.

What is Liquid Silicone Rubber?

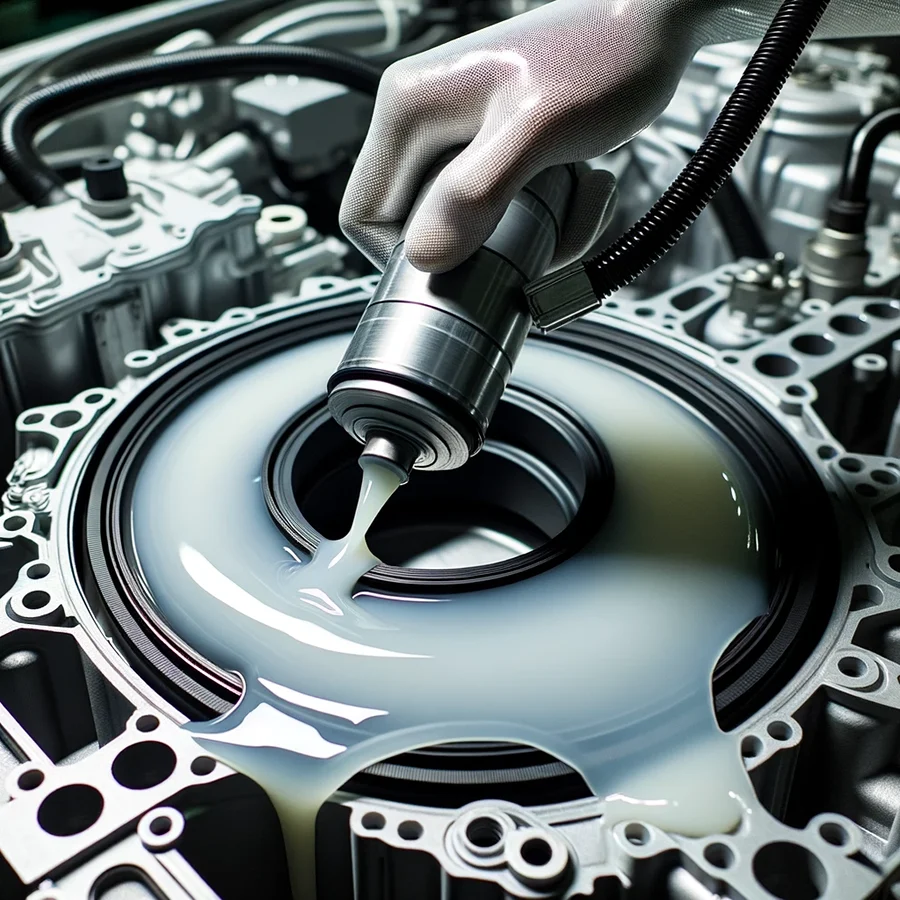

LSR is a type of silicone rubber that is made by mixing silicone oil and a curing agent. It is a liquid at room temperature, but it hardens into a solid rubber when it is cured.

LSR has a number of advantages over other materials, including:

- Excellent durability: LSR is resistant to a wide range of environmental conditions, including high temperatures, low temperatures, chemicals, and UV radiation.

- Excellent electrical properties: LSR is a good insulator, which makes it ideal for electrical applications.

- Good processability: LSR can be molded into a variety of shapes and sizes.

How is LSR used in automotive electrical components?

LSR is used in a variety of automotive electrical components, including:

- Connectors: LSR is used to seal and insulate electrical connectors. This helps to prevent corrosion and electrical shorts.

- Cables: LSR is used to coat electrical cables. This helps to protect the cables from damage and corrosion.

- Switches: LSR is used to make switches waterproof and dustproof.

- Sensors: LSR is used to seal and protect sensors from the environment.

- LEDs: LSR is used to seal and insulate LEDs. This helps to improve the performance and reliability of LEDs.

Benefits of using LSR in automotive electrical components:

LSR offers a number of benefits in automotive electrical components, including:

- Improved reliability: LSR is more durable than other materials, which can help to extend the life of electrical components.

- Reduced maintenance: LSR is less prone to corrosion and wear, which can reduce the need for maintenance.

- Improved safety: LSR can help to prevent electrical shorts and fires.

Conclusion:

LSR is a versatile and high-performance material that is well-suited for a variety of automotive electrical components. As the automotive industry continues to evolve, LSR is likely to play an even greater role in the development of new and innovative electrical systems.

Additional thoughts:

As a car enthusiast, I’m always looking for ways to improve the performance and reliability of my vehicles. Liquid Silicone Rubber Injection Molding is one of the most exciting new technologies I’ve seen in recent years. I believe that LSR has the potential to revolutionize the automotive industry, and I’m excited to see how it is used in the future.

Conclusion:

I hope you found this blog post informative. If you have any questions or comments, please feel free to leave them below.