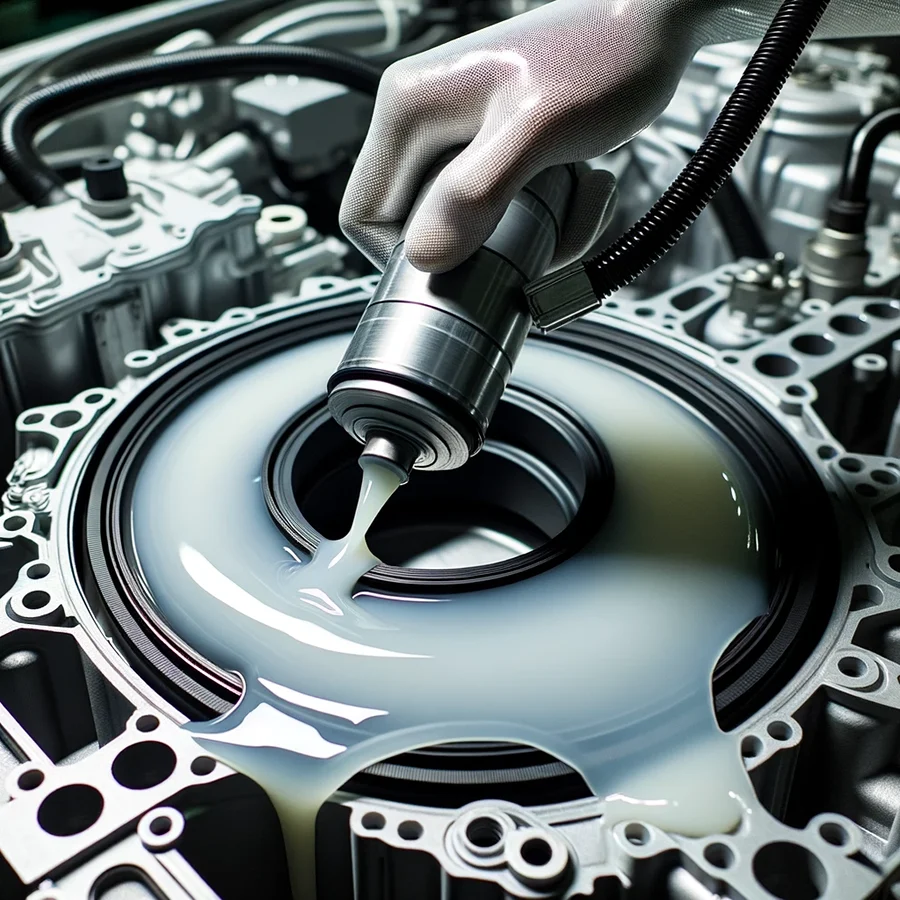

Automotive seals are an essential part of any vehicle, preventing water, dust, gases, and other harmful substances from entering the car. Traditional automotive sealing materials include rubber, plastic, and metal, but they all have some drawbacks. Rubber seals are prone to aging and damage, plastic seals may not be able to withstand high temperatures or low temperatures, and metal seals can be too heavy or expensive.

LSR injection molding is a new automotive sealing solution that offers many advantages. LSR material is a liquid silicone rubber that can be injection molded into a variety of shapes and sizes. LSR material has excellent heat resistance, chemical resistance, and weather resistance, and it can bond to a variety of surfaces.

1. What is LSR injection molding?

LSR injection molding is a process of injecting liquid silicone rubber into a mold. LSR material is a high-performance polymer made of silicon atoms. LSR material has excellent heat resistance, chemical resistance, and weather resistance, and it can bond to a variety of surfaces.

2. How is LSR injection molding used in automotive sealing?

LSR injection molding can be used to manufacture a variety of automotive seals, including:

- Engine cover seals

- Door seals

- Window seals

- Trunk seals

- Fuel tank seals

LSR injection molding can be used to manufacture seals with complex shapes and sizes that meet a variety of performance requirements.

3. What are the advantages of LSR injection molding over traditional automotive seals?

LSR injection molding offers several advantages over traditional automotive seals, including:

- Durability: LSR material has excellent heat resistance, chemical resistance, and weather resistance, which can extend the life of seals.

- Sealing: LSR seals have excellent sealing properties, which can prevent water, dust, gases, and other harmful substances from entering the vehicle.

- Cost-effectiveness: LSR injection molding is a highly efficient manufacturing process that can reduce the cost of seals.

- Automotive silicone: LSR material is a type of automotive silicone, which is specifically designed for use in automotive applications. Automotive silicone has been tested and certified for use in automotive applications, and it meets all the requirements for safety and performance.

4. Applications of LSR injection molding in the automotive industry

The use of LSR injection molding in the automotive industry is increasing. Here are some examples:

- Tesla uses LSR injection molding manufacture the door seals for its Model 3.

- Ford uses LSR injection molding to manufacture the trunk seals for its F-150.

- General Motors uses LSR injection molding to manufacture the fuel tank seals for its Chevrolet Bolt.

5. The future of LSR injection molding

As the automotive industry demands higher-performance and lower-cost seals, LSR injection molding is expected to continue to be a leading technology in the automotive sealing industry.

6. Challenges of LSR injection molding

LSR injection molding also presents some challenges, including:

- Material cost: LSR material may be more expensive than traditional automotive sealing materials.

- Process complexity: LSR injection molding is a more complex process than traditional automotive sealing processes.

7. Trends in LSR injection molding

As LSR injection molding technology continues to develop, the following trends are expected:

- Reduced material cost: As LSR material production scales up, material costs are expected to decline.

- Simplified process: LSR injection molding processes are expected to be simplified to reduce production costs.

- Expanded applications: LSR injection molding is expected to be used in more automotive components, including engines, transmissions, and chassis.

Conclusion:

LSR injection molding is a promising new automotive sealing solution with many advantages. LSR material has excellent heat resistance, chemical resistance, and weather resistance, and it can bond to a variety of surfaces. LSR injection molding can be used to manufacture seals with complex shapes and sizes that meet a variety of performance requirements. As the automotive industry demands higher-performance and lower-cost seals, LSR injection molding is expected to continue to be a leading technology in the automotive sealing industry.

Additional content

As an automotive modification and repair expert, I believe that LSR injection molding is a very promising automotive sealing solution. It has many advantages that traditional sealing materials cannot match, including:

- Excellent durability: LSR material can withstand high temperatures, low temperatures, chemicals, and other harsh environments.

- Excellent sealing: LSR seals have excellent sealing properties, which can prevent water, dust, gases, and other harmful substances from entering the vehicle.

- Good processability: LSR material can be injection molded into a variety of complex shapes and sizes of seals.

- Low cost: As LSR material production scales up, material costs are expected to decline.

- Automotive silicone: LSR material is a type of automotive silicone, which is specifically designed for use in automotive applications. Automotive silicone has been tested and certified for use in automotive applications, and it meets all the requirements for safety and performance.

I believe that LSR injection molding has the potential to revolutionize the automotive sealing industry. It is a versatile and high-performance solution that offers many advantages for automotive applications. I am excited to see how this technology is used to improve the safety, performance, and efficiency of vehicles in the future.